What is Overcast Control? How to effectively control the Overcast height of cast-in-place piles?

What is concrete overcast? What are the problems caused by overcast?

During the construction of cast-in-place piles, the elevation of the pile top is generally located at the bottom of the foundation pit, and there is a certain height difference with the construction surface. When pouring on site, it is often the on-site construction personnel who judge whether the concrete is poured to reach the elevation of the pile top based on experience.Due to manual judgment based on experience, there are often large errors. During the on-site construction process, if there is too little concrete poured, it may cause a verified quality accident, and the later construction quality is difficult to guarantee, which will affect the construction progress.In order to avoid problems caused by insufficient concrete poured, during the construction of the cast-in-place pile, in order to ensure the quality of the concrete at the top of the pile, overcast is generally carried out, and the height of the over-filling is generally 0.5-1.0m.However, due to the experience of the construction personnel and the difference in level, the overcast error is extremely large, and the height of the overcast often exceeds 2m, and some even reach more than 5m.

The problem of overcast of cast-in-place piles not only caused waste of concrete materials, but also caused difficulties in excavation of the earth and the removal of pile heads and outbound transportation costs, which greatly increased the project cost, and even encountered incidents such as cost claims from the construction unit.

How to effectively control the height of poured concrete?

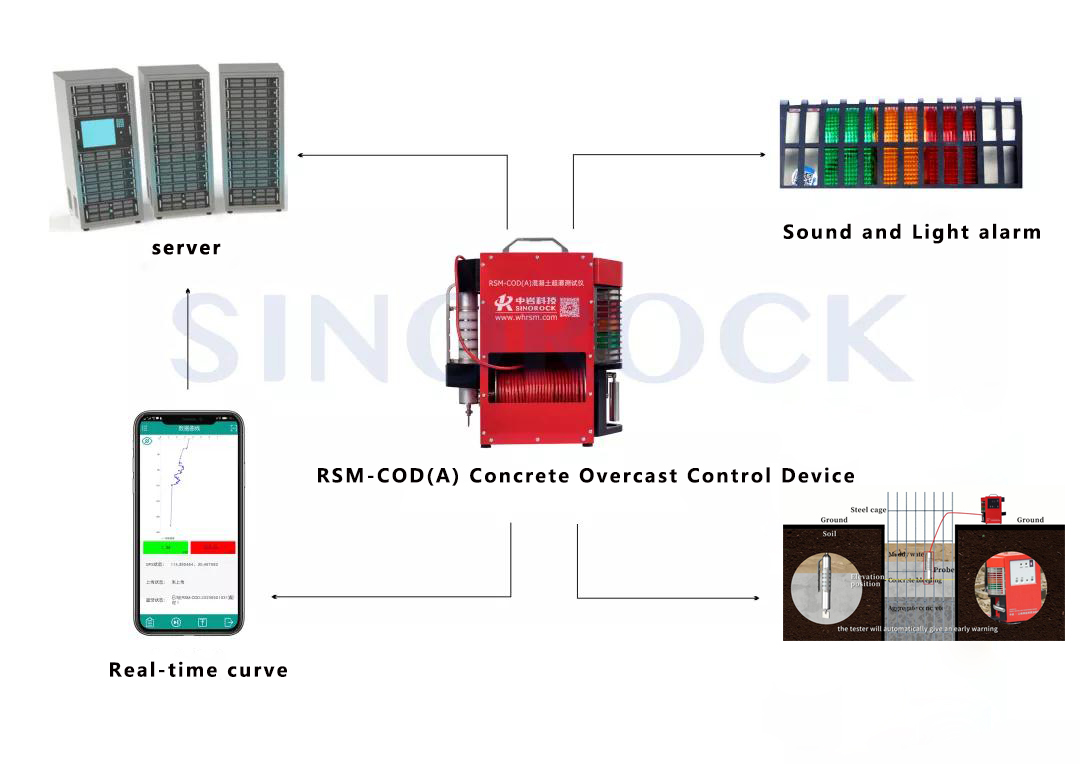

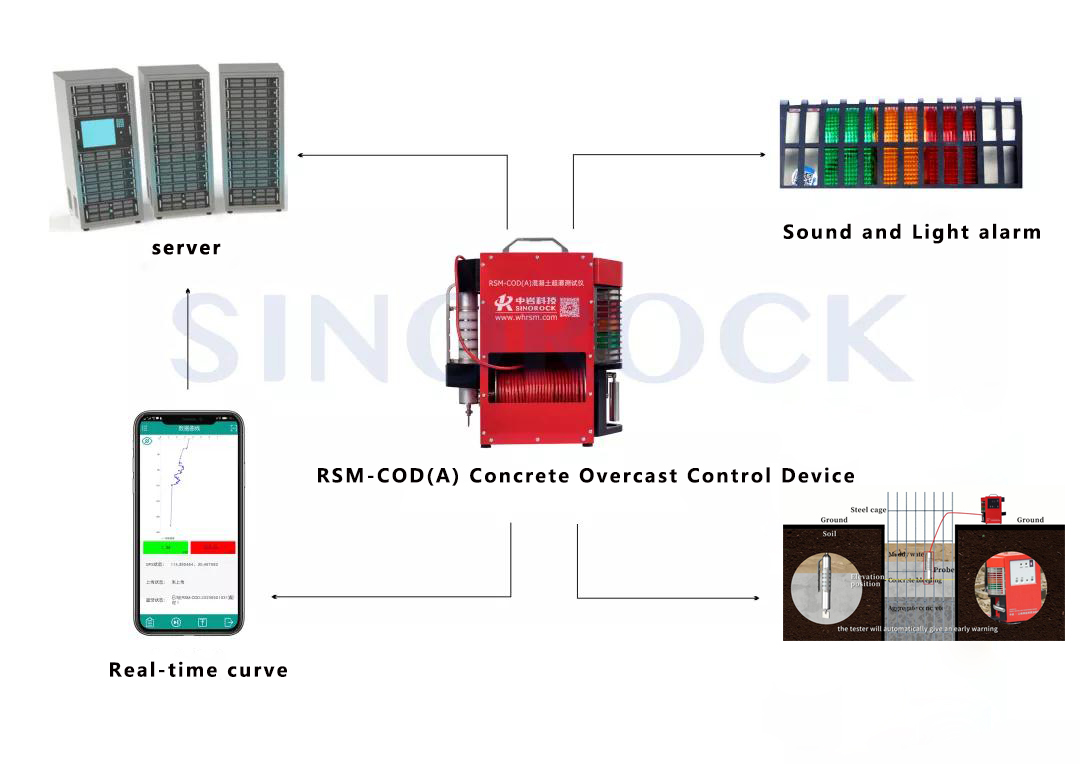

In order to solve the problem of accurate measurement of the pile top elevation during the concrete pouring process, accurately control the reasonable pouring height of the pile head, ensure the quality of the pile head, and save the project cost, Sinorock has developed the RSM-COD(A) concrete overcast control device. Committed to solving the problem of concrete overfilling, reducing human errors and risks, and improving the management level of the enterprise.

The RSM-COD(A) Concrete Overcast Control Device can intelligently detect the pouring state of the concrete through the sensor, and judge whether the concrete has reached the design elevation. When the concrete is poured to a position close to the elevation, the instrument will automatically give an early warning, prompting to slow down the pouring speed; when pouring continues to the position corresponding to the elevation, the instrument will alarm and stop pouring.

At the same time, the data collected during the pouring process can be viewed in real time through an Android phone, and managers can effectively control the pouring process and the construction progress of the cast-in-place pile in real time through smart terminal equipment.

At the same time, the data collected during the pouring process can be viewed in real time through an Android phone, and managers can effectively control the pouring process and the construction progress of the cast-in-place pile in real time through smart terminal equipment.

This device solves the problem of overcast or underfilling caused by experience in the traditional manual operation process, improves the qualification rate of concrete cast-in-place piles, and reduces the waste of concrete resources. At the same time, environmental pollution caused by discarded concrete blocks is reduced, which can effectively ensure construction quality and improve construction efficiency. This equipment is generally suitable for pouring concrete piles of various projects, including dry hole and underwater concrete piles.

Advantages of RSM-COD(A) Concrete Overcast Control Device

Intelligent control · Sound and light warning

After the probe is installed and lowered, there is no need for manual operation during the whole process, and the instrument automatically collects; the concrete is poured close to the test surface, the instrument automatically warns, and the yellow light indicator flashes to remind you to slow down the pouring speed; the concrete reaches the test surface, the instrument automatically alarms, and the green indicator is always on light.

Well-designed and adaptable

Well-designed and adaptable

1. Taking into account the impact of the harsh environment on the construction site, the winch and the equipment box are designed with isolation, and the dry and wet partitions are used to facilitate the recovery and washing of the probe cables on site.

2. Unique grooves structure, the cable tie can be installed directly, and can be easily pulled out after the test is completed.

3. The probe is made of alloy material, and the cable has a built-in Kevlar cable, which can withstand a pulling force of 100kg.

One-key calibration, real-time display

One-key calibration, real-time display1. The equipment can calibrate the test concrete parameters with one key, and the calibration data of the same site can be obtained through the network.

2. The real-time collected data can be viewed through the Android mobile APP and drawn into the corresponding curve.

Accurate test · Ultra-long standby

Accurate test · Ultra-long standby1. Multi-parameter control, accurately distinguishing different media such as mud, water, floating paddle and concrete during the pouring process, can accurately test the concrete reaching surface, and the accuracy is controlled within 0.05m.

2. Equipped with a large-capacity battery, it can work continuously for more than 48 hours, and it can be used while charging.

What value can the use of RSM-COD(A) Concrete Overcast Control Device bring?

Economic Value

Concrete Overcast Control Device can effectively reduce costs and increase profits. Taking conventional building foundation piles with an average length of 50 meters, an average pile diameter of 2 meters, and an average overfilling of 2 meters, the price of C30 concrete is 460 yuan/m3 as an example, which directly saves 288 per thousand. Ten thousand yuan. (Does not include pile cutting and waste disposal costs).

Management value

The overcast device can intelligently record the construction data of each project, effectively standardize the construction behavior, improve the construction efficiency, make the construction evidence-based, and reduce disputes. As a manager, you can understand the construction progress in real time and improve the extensive management mode, especially in the bidding of large-scale projects, and enhance your competitiveness.

Social value

Avoid environmental pollution caused by waste disposal caused by over-irrigation, innovate construction techniques and methods, and promote traditional construction to "smart construction".

How should the overcast device site be operated?

Two operation modes, both efficiency and process control, seven simple steps to solve the problem of overcast.

1. Calibration of concrete parameters

Before testing, you first need to calibrate the parameters of the poured concrete, place the probe in the concrete (submerged in the concrete), press and hold the calibration button on the instrument, the green indicator of the device will flash and the buzzer will be on for a long time, which means the calibration is successful.

2. Banding the probe

Hoist the rebarcage to a suitable location and tie the probe to the rebar cage by passing through binding grooves on the probe.

3. Lowering Rebar Cage

After the probe is secured, lower the rebar cage, during which the probe cable should also be lowered simultaneously and remain movable without being held down by the cage. Once the cage is lowered into place, tie the probe cable to fixed objects on the ground so that the cable will not fall off into the concrete during pouring.

4. Concrete Pouring

After the probe is in place, start pouring concrete. Protect the probe cable during the pouring process.

5. Early warning of equipment to slow down pouring

While pouring concrete, if the concrete is reaching the designated elevation, the device yellow indicator will automatically flash for alarm, at which point the pouring should be slowed down.

6. Equipment alarms, pouring stops

The green indicator stays on permanently and the buzzer keeps beeping to indicate that the concrete level has reached the designated position, at which point the pouring should be stopped.

7. Probe Retrieval and Cleaning

Once the concrete pouring is completed, untie and pull the probe cable until the probe is dragged out.Pay attention to site safety during the process.once retrieved, the probe should be rinsed with clean water immediately to clean away any concrete residue that may solidify and affect device service life.

What are the functions of the app and how to use it?

RSM-COD(A) is equipped with an Android APP which can be used to view site test data, input project information and pile information, and transfer these data to a designated server. The APP can also update device firmware via Bluetooth, which is simple and convenient.

Case

For a high-speed project in Anhui, the construction party used RSM-COD(A) Concrete Overcast Control Device developed and produced by Sinorock. to test and control the height of the concrete pouring surface during the concrete pile pouring process.

At the site, first take out the probe of the tester before the last section of the steel cage is completely inserted into the hole. Use a cable tie to tie the probe 3-5cm above the top stirrup of the reinforcement cage (or other design elevation position), and the distance is based on the bottom of the probe.

After the probe is fixed, the steel cage can be lowered to the designated position. At this time, you can turn on the equipment and wait for pouring.

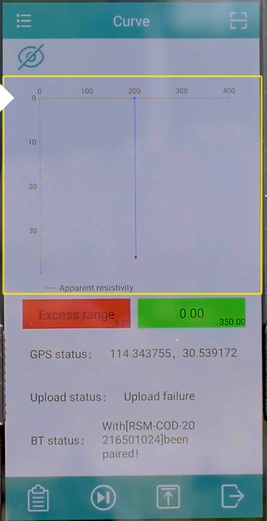

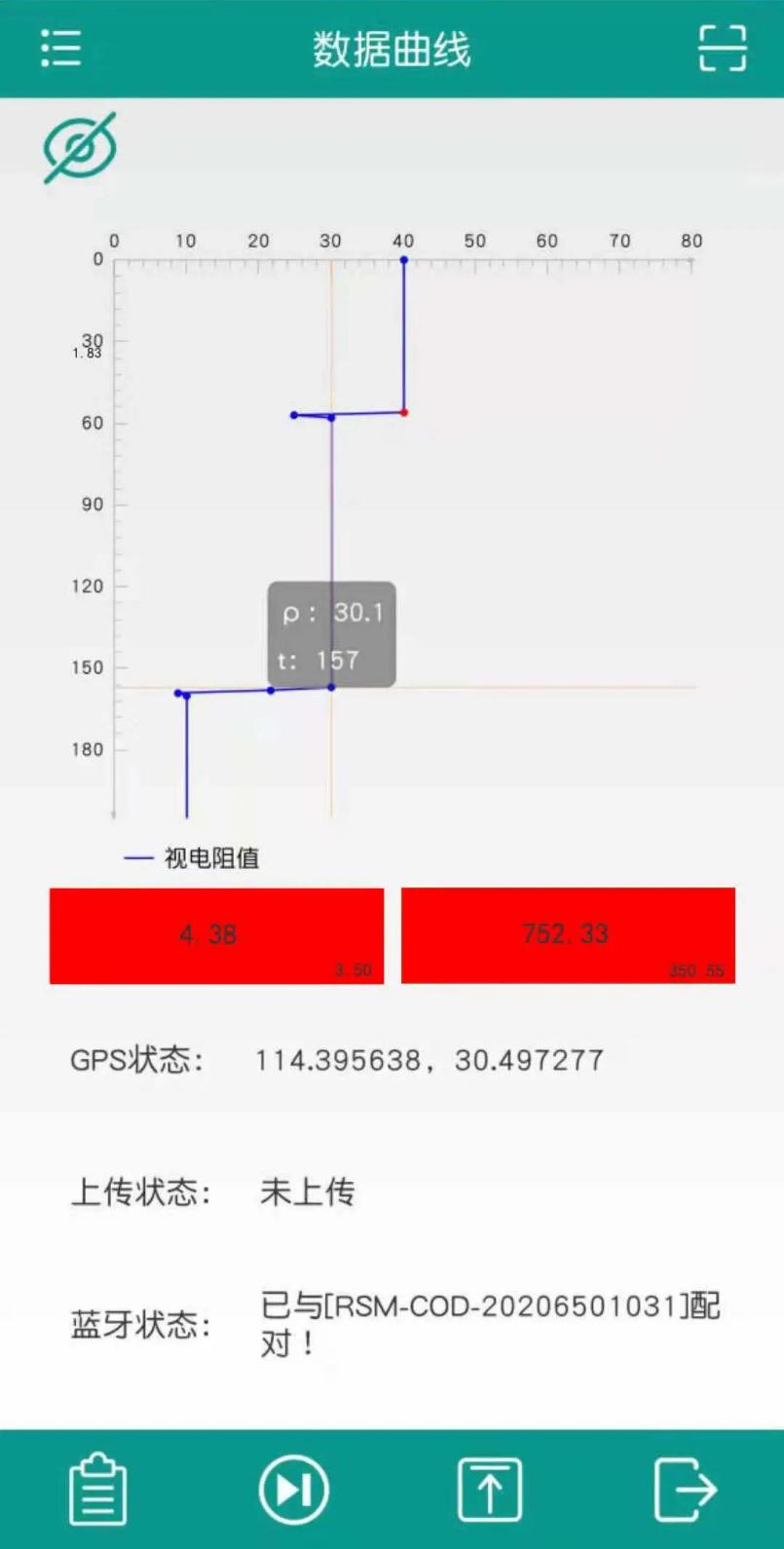

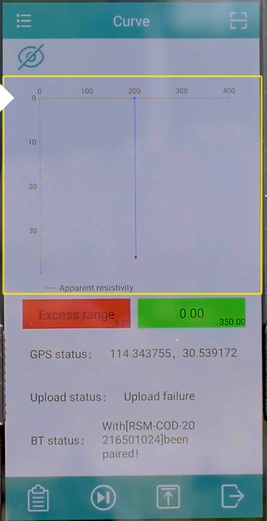

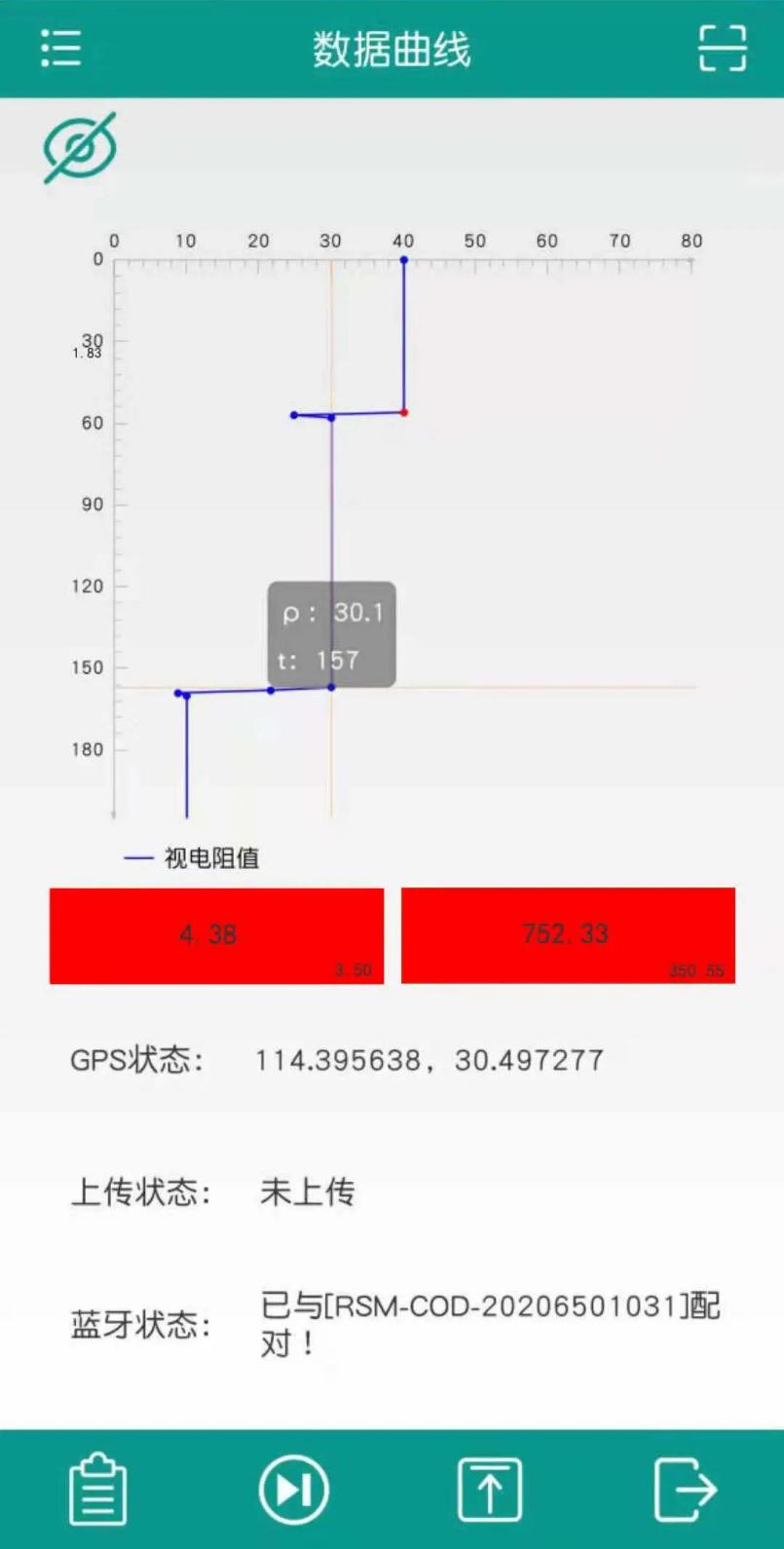

You can also open the mobile app and connect the mobile phone to the device via Bluetooth. After the connection is successful, you can view the real-time resistivity data collected by the probe. Now we can see that the apparent resistivity of the mud is about 40Ω·m.

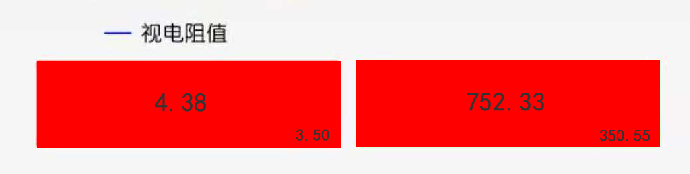

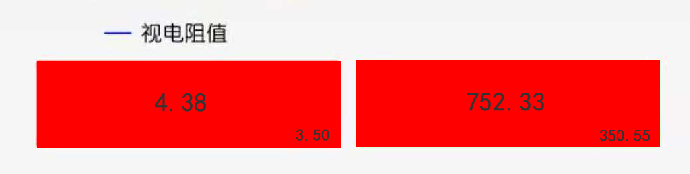

After the concrete truck comes, start pouring. With the pouring of concrete and the elevation of the pouring surface, it can be seen that the apparent resistivity curve value will decrease step by step. After the apparent resistivity drops below the calibrated value, the yellow indicator light of the device will start to flash. At this time, the torque motor on the probe will also start to rotate synchronously. If you use the app, you can see that the torque motor current value display area on the app starts to change in value. At this time, the yellow light starts to flicker, indicating that the concrete pouring surface is close to the probe, and the on-site staff can slow down the pouring speed.

Continue pouring, we can find that the torque motor current value displayed on the app will slowly increase. When the current value of the torque motor exceeds the calibration value, the green light of the equipment will start to flash with a buzzing sound to remind the staff to stop pouring.

Visual resistivity

After pouring is completed, after the staff pulls out the hopper and the pipe, the probe needs to be pulled out and rinsed for next use.

Visual resistivity

After pouring is completed, after the staff pulls out the hopper and the pipe, the probe needs to be pulled out and rinsed for next use.